Sites and subsidiaries

A fully integrated biotechnology company

From our roots in Mainz, Germany, BioNTech has become a next-generation global biotechnology company. Together with our subsidiaries, we are pioneering the development of novel immunotherapies and vaccines, advancing in-house manufacturing and commercial capabilities while driving the use of artificial intelligence in drug discovery, design and development.

Innovation across borders: BioNTech’s R&D infrastructure

BioNTech's commitment to pioneering the development of novel immunotherapies and vaccines is underpinned by its robust research and development (R&D) infrastructure. With key R&D locations strategically positioned across five continents, we enhance our ability to innovate and address some of the world’s most pressing health challenges. Our headquarters in Mainz, Germany acts as a central hub for scientific research and technological advancements, while additional R&D centers in the United States, the United Kingdom and other countries and regions support collaborative efforts in exploring new therapeutic frontiers. These facilities focus on harnessing advanced technologies, such as artificial intelligence, to accelerate drug discovery and design, ultimately aiming to improve patient outcomes worldwide.

Building manufacturing capabilities: A global approach

To successfully bring immunotherapies to patients and vaccines to people around the world, we believe it is crucial to have in-house manufacturing capabilities. With our manufacturing sites for mRNA and antibodies as well as our innovative mRNA manufacturing solution called BioNTainer, our goal is to have a strong global manufacturing network. The network aims to integrate fully automated processes and enable scalable and demand-driven manufacturing.

Our manufacturing centers

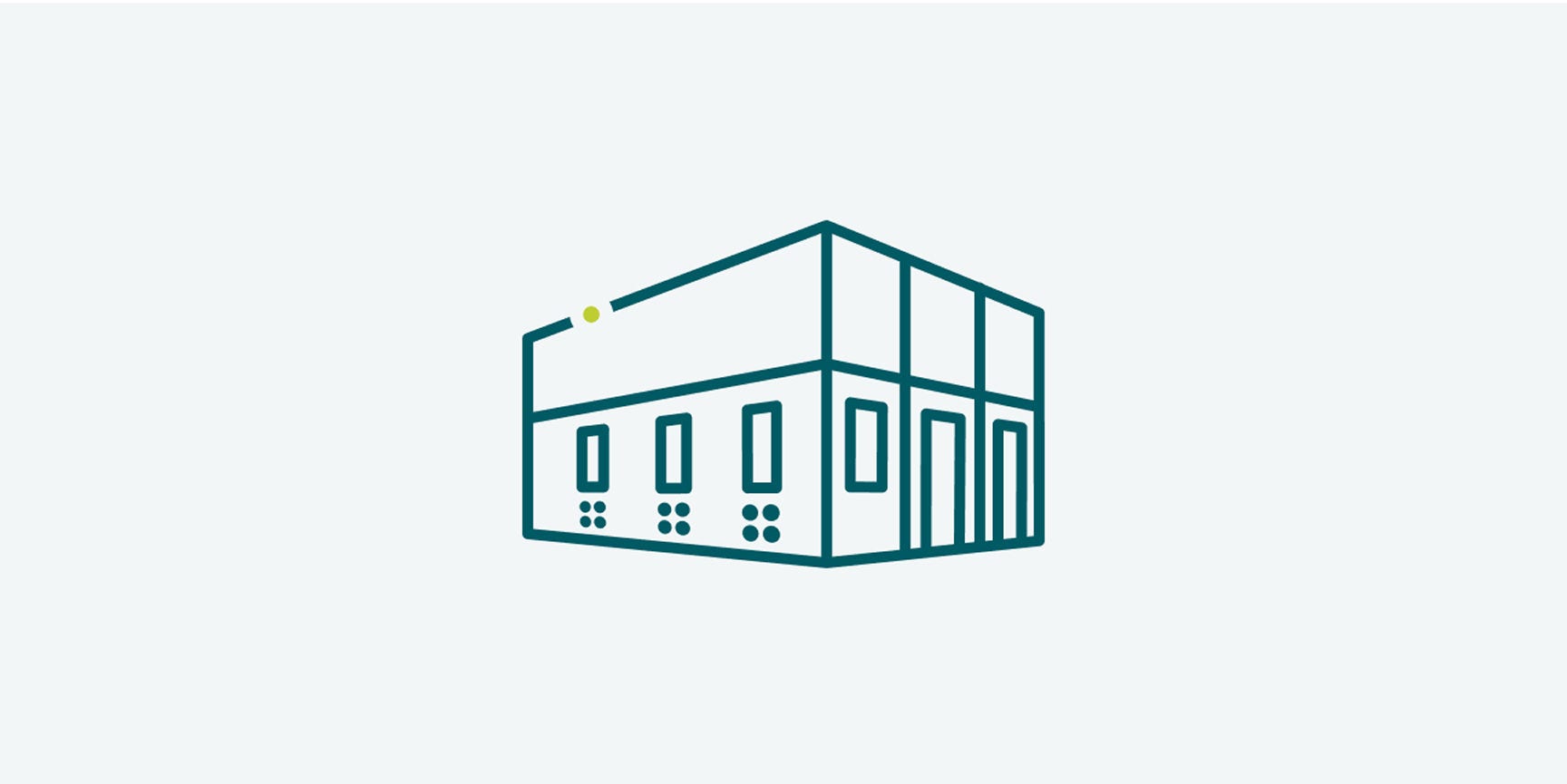

BioNTainer – a novel solution to enable manufacturing of mRNA-based products worldwide

The BioNTainer is an innovative technology based on high-tech, digitally enabled modular units designed for scalable manufacturing of a range of mRNA-based products.

Key features

Modular design

Each BioNTainer unit consists of six to eight ISO-sized containers and has been designed to manufacture mRNA material for drug substance, drug product and filling processes. This modular design allows for easy transportation and standardized setup of BioNTainer-based manufacturing sites.

State-of-the-art technology

Each BioNTainer features a clean room with standardized equipment and software components that can be regularly updated with the goal of remaining one of the most sophisticated mRNA manufacturing facilities globally.

Versatile manufacturing capabilities

BioNTainer-based facilities can be equipped to manufacture a range of mRNA-based products tailored to regional needs.

Use cases

Clinical-scale manufacturing:

BioNTainer units can be used to manufacture mRNA-based product candidates for clinical trials.

Commercial-scale manufacturing:

Once an mRNA-based product is approved, BioNTainer units can be used to manufacture large quantities required for widespread distribution. This can help address the need during endemic or pandemic situations.

BioNTainer locations

Based on prototypes in Marburg, Germany, BioNTech is currently building BioNTainer-based facilities in Kigali, Rwanda and Melbourne, Australia.

BioNTech production plant Marburg, Germany

BioNTech production site Kigali, Rwanda

Preparing for the future: Advancing commercial capabilities

BioNTech is actively preparing to expand its commercial capabilities to support the anticipated launch of oncology products, pending regulatory approval. We aim to establish a specialized oncology sales force in key markets such as the United States and Europe, ensuring a strong presence to meet the needs of healthcare providers and patients. Additionally, we plan to leverage strategic partnerships for co-commercialization to maximize global reach and impact. These efforts reflect our commitment to becoming commercial-ready in oncology and support our goal of delivering innovative medicines to people worldwide.

Explore more

Collaborators

Pipeline